Depending on who you ask, the common phrase “close the loop” might refer to anything from achieving daily fitness goals on your smartwatch to finishing a crocheting project.

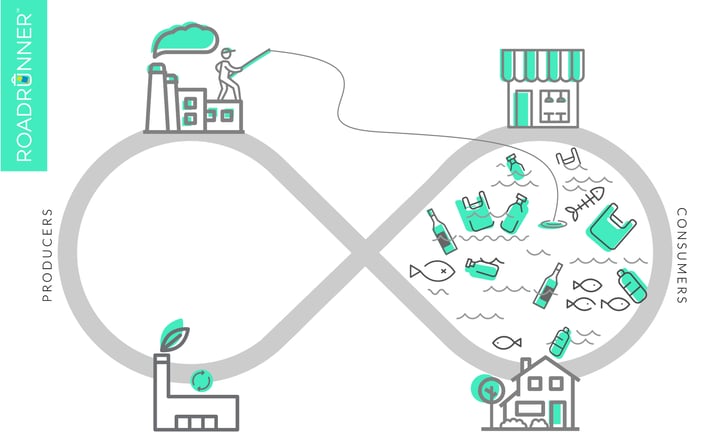

But in sustainability, it’s referencing a gold-standard. An upper echelon. A system designed to repeat itself infinitely. Although, unless the right ingredients and inputs are involved, closing the loop can be very difficult to achieve.

By many accounts, "closed-loop recycling" is the key to a truly circular economy. As companies in manufacturing, shipping, and retail prepare their supply chains for the next big challenge, it’s helpful to learn the difference between systems, who’s succeeding with closed-loop, and how your business can bring it full circle.

Closed-Loop vs. Open-Loop Recycling

By definition, closed-loop recycling is the manufacturing process that leverages the recycling and reuse of post-consumer products to supply the material used to create a new version of the same product.

Closed-loop recycling sees products retain their value indefinitely.

In a closed-loop recycling system, products are designed in a way that benefits the overall supply chain, emphasizing universal collection and recovery, ease of re-manufacturing, and economic feasibility.

Prime examples of closed-loop recycling products include glass used for bottles and jars, aluminum used for cans and tins, and a very limited amount of plastics. Glass and aluminum are infinitely recyclable with no degradation of quality, making them infinitely valuable to the loop. In fact, about 75% of all aluminum ever produced is still in use today. Unfortunately, only 2% of global plastic production is reused for the same or similar products.

Closed-loop differs from the far more widespread and achievable concept of open-loop recycling, which doesn’t depend on the output of the process. In this system, the end of the product life cycle can take multiple routes: recycled as raw material for new, yet inferior, products or rejected as waste.

Open-loop recycling sees products diminish in value over time.

In this sense, an open-loop system can be semi-circular or nearly linear depending on how much is recycled. When products are recycled in an open-loop system, the new items produced are of a lesser value than the original product—a process known as downcycling.

Cardboard and paper (which can be recycled five to seven times before unrecoverable loss in quality), many plastics, and in some cases, food waste don’t have the same structural advantages as aluminum and cardboard, which makes them better for open-loop use cases. Examples are countless, including PET plastic becoming fleeces and carpets and cardboard returning as cereal boxes and paper towels.

Companies finding success in this method include Chipotle repurposing discarded avocado pits to dye sustainable closing and Trex crafting deck planking using plastic grocery bags from Albertsons.

Developing a Closed-Loop Business Strategy

Advantages of closed-loop include drastic reduction in raw materials and preservation of natural resources, positive and sustainable brand perception, reduced fees and capacity concerns related to rising landfills, and improved energy efficiency.

And the numbers prove it. According to the Glass Packaging Institute, one kilogram of used glass cullet (crushed post-consumer glass) can replace 1.2 kilograms of virgin material. When cullet is used for just 10% of the remanufactured product, it leads to lower CO2 emissions by 5% and requires 30% less energy than producing it with virgin materials.

Meanwhile, creating new aluminum products from recycled aluminum saves more than 90%—and even as high as 95%—of the energy it would take to produce new metal.

So, in many cases, the most sustainable option is also the most profitable long-term. And across a number of industries, companies are championing closed-loop recycling.

At the most advantage are players in the glass bottle and aluminum can industries, like manufacturers Owens-Illinois Glass Company and Ball Corporation. However, sustainable businesses are creating new opportunities in other sectors, too.

Dell has been a leader in circular design, creating a closed-loop for the plastics used in computers and monitors, as well as a partnership with hard drive manufacturer Seagate to recover and reuse rare-earth magnets.

In the textiles and apparel industry, multiple companies have opted for circular sourcing. PANGAIA uses a closed-loop lyocell rayon made from bamboo, eucalyptus, and seaweed fibers as one of its materials. For Days, on the other hand, engineers its clothing with 100% organic cotton and provides customers a prepaid envelope to send them back in exchange for a new item on their site. The company re-pulps the old clothes and spins the fibers back into yarn used in the new clothing.

One of the trickiest challenges, rPlanet Earth has shown success transforming recovered PET plastic bottles and containers into new high-quality bottles and containers.

How do they do it? Demonstrated by these companies, developing a sustainable strategy begins with breaking the status quo.

How Can Your Business Close the Loop?

As mentioned, beginning or advancing closed-loop business practices and supply chain operations requires a top-to-bottom commitment. However, there are steps your business can take to close the loop on a daily basis.

Recycle Responsibly

Identifying valuable recyclable material in your business (particularly that which is ultra-effective in a closed loop) is a productive way to contribute to a closed-loop system, even if it’s not your own. Supply bottlenecks and increased demand during the COVID-19 pandemic highlighted just how important it was for manufacturers to receive recovered aluminum, glass, and cardboard boxes (which are often used to create new cardboard boxes).

If your business is developing its own closed-loop process, consider finding a recycling partner, like RoadRunner Recycling, with experience diverting recyclable material away from landfill and back into production.

Compost

Composting is the most-natural form of closed-loop recycling. Organic materials like plant and food waste decompose into a matter rich in nutrients and beneficial bacteria that’s used in the fertilization for the growing of new fruits, vegetables, and other organics. While each fruit or vegetable may be unique, the overarching cycle can be repeated continuously.

For a guide to workplace composting, read on here.

Make Smarter Purchasing Decisions

Deviating from single-use products and packaging can save your business in the long-term, especially for those products dependent on finite natural resources like aluminum or petroleum-based plastic.It may take some firm decisions to evolve your supply chain, but in the long-run, sourcing perpetually recycled material over virgin materials can be more cost-efficient, environmentally friendly, and sustainable for your business as a whole.